The Strategic Value of an Oil-Free Air Compressor

According to the Global Manufacturing Compressed Air Quality Report released by the Compressed Air and Gas Institute (CAGI) in 2024, nearly 68% of product quality issues in factories can be traced back to compressed air contamination. Among these cases, the costs incurred by oil-contaminated compressed air—including production line shutdowns, finished product scrapping, and equipment maintenance—account for an average of 12% to 18% of a factory’s annual operating expenses.

In modern manufacturing, product quality hinges on process purity. Contaminated compressed air can undermine quality, raise costs, and damage your reputation. For industries where air purity is critical, the solution is clear: invest in an oil-free air compressor. This isn’t just an upgrade—it’s a strategic move toward greater reliability and efficiency.

Guaranteeing Contaminant-Free Air

Lubricated compressors carry a constant risk of oil carry-over. Even with filters, microscopic oil can contaminate your air supply.

This is a critical failure point for sensitive sectors like:

Food & Beverage

Pharmaceuticals

Electronics

An oil-free air compressor eliminates this risk at the source. By design, air never contacts lubricating oil, ensuring inherent purity and protecting your products and processes.

Achieving True Cost Efficiency

The initial price of an oil-free model can be higher. But the real story is told by the Total Cost of Ownership (TCO).

Oil-lubricated systems incur hidden, ongoing costs:

Specialized compressor oil

Frequent oil and filter changes

Costly disposal of hazardous oily condensate

By removing these oil-related expenses, an oil-free air compressor significantly reduces your long-term operating costs.

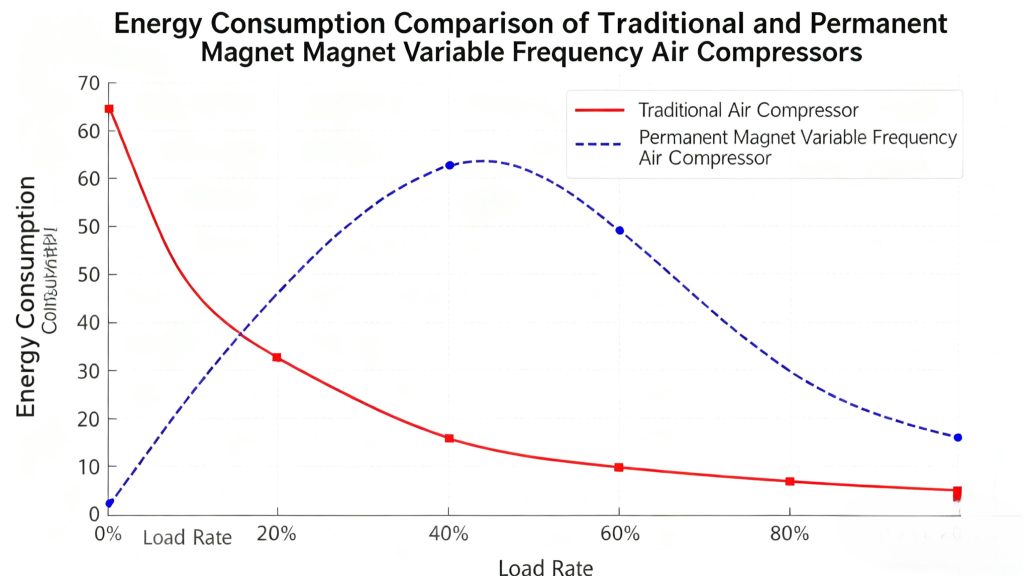

Boosting Energy Performance

Older oil-free models were sometimes less efficient. This is no longer the case.

Modern oil-free air technology incorporates features like Variable Speed Drives (VSD), which match energy use to real-time demand. The absence of oil also reduces internal friction. For 24/7 operations, these efficiency gains lead to substantial annual energy savings.

Supporting Sustainability Goals

An oil-free system is a greener choice. It eliminates the generation of hazardous oily waste, simplifying regulatory compliance.

This move enhances your sustainability profile and aligns with international clean air standards (ISO 8573-1). It’s an investment that benefits both your production line and the planet.

Making the Right Choice

“Oil-free” includes different technologies, like screw and centrifugal compressors. Your choice depends on your air flow, pressure, and purity needs.

For most industrial applications requiring Class 0 air, oil-free screw compressors offer a strong balance of performance and durability. Partner with a manufacturer known for robust, long-lasting designs.

Conclusion: A Smart Investment for Modern Factories

Transitioning to oil-free air is a forward-thinking strategy. It directly enhances product quality, controls operational costs, and supports environmental goals.

When evaluating providers, consider specialized manufacturers. Companies like Seize Air focus on engineering reliable and energy-efficient oil-free screw air compressors, offering robust solutions for demanding industrial applications.

English

English

Chine

Chine

Russia

Russia

France

France

Spain

Spain

Arab

Arab