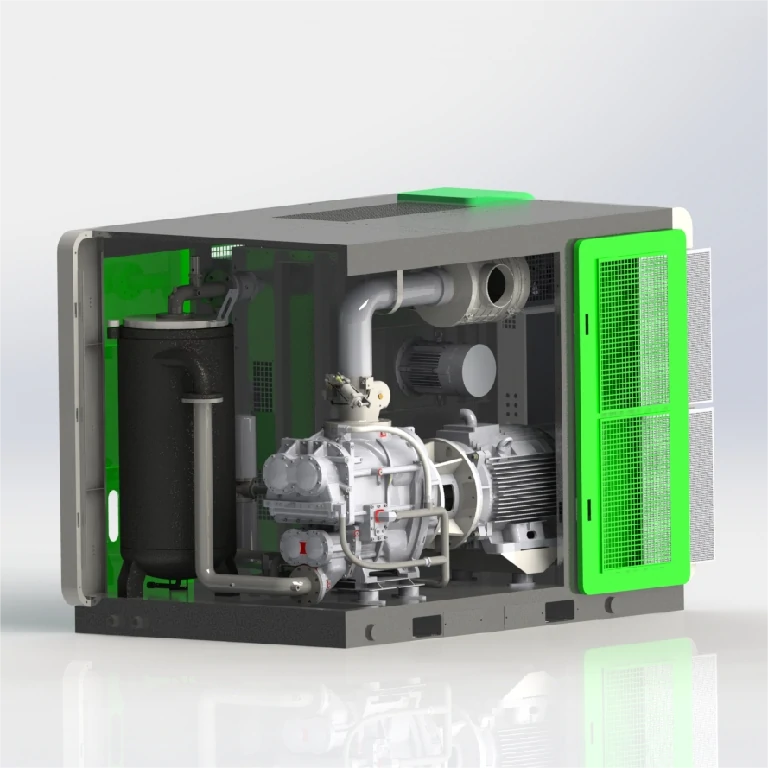

Permanent magnet variable frequency two-stage compression screw air compressor

Working pressure: 4.5-12.5 bar / 65-181psig

Capacity: 0.5-85.5 m3/min / 17.7-3018.2 cfm

Power: 15-330 kw

Product advantages

01 Two-stage pressure customized host, average efficiency improvement of 20%

1. Utilize the principle of reducing compression ratio and reducing reflux leakage, close to isothermal compression, and improve the efficiency by 12-15% compared with single-stage compression;

2. The efficiency of pressure customized two-stage host is 5~8% higher than that of ordinary two-stage host;

02 Permanent magnet/high-efficiency variable frequency motor: average efficiency improvement of 5%

1. Eliminate no-load;

2. Eliminate excess pressure;

3. Countless start and stop, and high efficiency can be maintained during frequency conversion;

4. The motor efficiency is first-level energy efficiency;

03 Dual frequency conversion system: constant temperature, constant pressure

1. Constant temperature output: Generally, the constant temperature is set at around 81℃ to optimize the oil lubrication effect and avoid high temperature tripping;

2. Constant pressure output: Constant pressure control accuracy is ±0.005MPa, which improves the user’s finished product rate and product quality Quality;

04 Customized large cooling system

1. Increase the radiator area, anti-rust and anti-corrosion coating on the surface, easy to clean and long life, good heat dissipation and constant temperature effect;

2. Low oil temperature to avoid oil circuit glue and carbon deposition and high temperature;

3. The unit runs smoothly and the life is increased, avoiding high temperature shutdown;

4. Adopt enlarged frequency conversion fan, centrifugal fan above 75kw, uniform heat dissipation, low noise and large air volume;

05 Customized enlarged oil and gas system

1. Enlarged oil and gas system, small pipeline pressure loss;

2. Good heat dissipation effect, stable equipment operation;

3. Good oil and gas separation effect, the oil content of the outlet gas is less than 3PPM;

06 Customized double air intake filtration and external air intake guarantee

1. External air intake filter: filter dust cotton, washable, to prevent impurities from entering the machine body;

2. The air filter of the air compressor adopts horizontal air filter intake, and the filtration accuracy reaches 1μm;

3. The two-layer filtration can well protect the use of the air compressor host and lubricating oil, and reduce the failure rate of the electrical parts;

4. The air filter inlet is equipped with a guide device to ensure the low external air intake temperature and improve the efficiency of the whole machine by 2%;

07 Intelligent control system + remote Internet of Things

1. On-site, mobile phone, and computer simultaneously display: operating status, operating data, fault warning, etc.;

2. Real-time online monitoring: pressure, power, temperature fluctuations;

3. Users, service providers, and manufacturers display simultaneously to improve communication efficiency and better escort the stable production of enterprises;

08 Ambient temperature design and test standards: 12℃ higher than the international standard

1. The industry international design standard is 40℃, and SEIZE strictly follows 52℃ Standard design;

2. It can be shipped only after passing the 52℃ high temperature test standard;

09 Overall piping system-stainless steel precision drawing tube

1. Simple structure, avoiding aging and oil leakage;

2. The precision drawing tube has high internal and external finish and small pipeline pressure loss;

3. It will never rust and has an overall beautiful appearance;

10 Built-in and reserved heat recovery

1. Zero heating cost: Use the heat discharged from the air compressor to the environment to generate hot water, and the recovery efficiency can reach about 60% of the unit input power;

2. It is beneficial to the heat dissipation of the air compressor: reduce the power consumption required for heat dissipation, which is beneficial to the smooth operation of the air compressor;

3. It is beneficial to environmental protection: reduce the heat discharged by the air compressor into the environment;

4. Repeated consumption reduction of enterprises: The recovered hot water can be used for employee bathing, preheating of boiler water, circulating air conditioning water, etc.

Technical parameters

| Machine Model | Max Working Pressure | SVC-15A II | SVC-18A II | SVC-22A II | SVC-30A II | SVC-37A II | ||||

| Compressor | Air Delivery (m3/min) | 4.5kgf/cm2 | 1.0~3.9 | 1.2~4.8 | 1.6~6.4 | 2.1~8.8 | 2.6~10.3 | |||

| 5.5kgf/cm2 | 0.9~3.5 | 1.1~4.3 | 1.5~6.1 | 1.9~7.7 | 2.4~9.5 | |||||

| 6.5kgf/cm2 | 0.8~3.2 | 1.0~4.0 | 1.2~4.8 | 1.8~7.0 | 2.2~8.7 | |||||

| 7.5kgf/cm2 | 0.7~3.0 | 0.9~3.8 | 1.1~4.5 | 1.6~6.8 | 1.9~7.5 | |||||

| 8.5kgf/cm2 | 0.7~2.9 | 0.8~3.4 | 1.1~4.3 | 1.5~6.2 | 1.8~7.4 | |||||

| 10.5kgf/cm2 | 0.6~2.4 | 0.7~2.9 | 0.8~3.4 | 1.2~4.7 | 1.5~6.0 | |||||

| 12.5kgf/cm2 | 0.5~2.0 | 0.7~2.7 | 0.7~2.9 | 1.1~4.3 | 1.4~5.6 | |||||

| Outlet Temperature(℃) | Ambient temperature+15℃ | |||||||||

| Outlet Pipe Diameter(inch) | 1 1/2 | 1 1/2 | 2 | 1 1/2 | 2 | 1 1/2 | 2 | 2 | ||

| Transmission method | Direct Driven | |||||||||

| Lubricant Requirement(L) | 24 | 24 | 50 | 24 | 50 | 24 | 50 | 50 | ||

| Ventilation method | 25-100% automatical control, constant pressure output | |||||||||

| Oil content(ppm) | ≤3 | |||||||||

| Concuss(mm/s) | ≤7 | |||||||||

| Max Working Ambient Temperature(℃) | 52℃ | |||||||||

| Electric Motor | Power (kw) | 15 | 18.5 | 22 | 30 | 37 | ||||

| Starting method | Frequency conversion start | |||||||||

| Voltage | 380V/440V/660V | |||||||||

| Protection Level | IP55 | |||||||||

| Cooler | Cooling Type | air cooling or water cooling | ||||||||

| Control method | Frequency conversion constant temperature control | |||||||||

| Fan Power(KW) | 1.1 | 1.1 | 1.35/1.1 | 1.35/1.1 | 1.5/1.35 | |||||

| Cooling Air Volume(m3/min) /Cooling water(t/h) | 100 | 110 | 120 | 140 | 160 | |||||

| Safety Indicating Device | safety valve/exhaust high tempenture protection/exhaust high pressure protection/over current protection/less phase protection/reversed phase protection | |||||||||

| Maintenance instructions | air filter/oil filter/oil-gas separator/lubricated oil | |||||||||

| Microcomputer control | digital temperature/pressure display controller/fully automatic operation/stop controller muti-machine interconnection controller(optional)/central monitoring extension function(optional) | |||||||||

| Noise(db) | 65 | 65 | 65 | 68 | 68 | |||||

| A Weight(kg) | 1000 | 1100 | 1300 | 1100 | 1350 | 1150 | 1650 | 1450 | ||

| Air-Cooling | External Dimension | L(mm) | 1550 | 1550 | 1700 | 1550 | 1700 | 1550 | 1850 | 1700 |

| W(mm) | 980 | 980 | 1130 | 980 | 1130 | 980 | 1180 | 1130 | ||

| H(mm) | 1300 | 1300 | 1430 | 1300 | 1430 | 1300 | 1430 | 1430 | ||

| W Weight(kg) | 1000 | 1100 | — | 1100 | — | 1150 | 1650 | — | ||

| Water-Cooling | External Dimension | L(mm) | 1500 | 1500 | — | 1500 | — | 1500 | 1800 | — |

| W(mm) | 1000 | 1000 | — | 1000 | — | 1000 | 1320 | — | ||

| H(mm) | 1260 | 1260 | — | 1260 | — | 1260 | 1370 | — | ||

| Machine Model | Max Working Pressure | SVC-45A II | SVC-55A/W II | SVC-75A/W II | SVC-90A/W II | ||||||||

| Compressor | Air Delivery (m3/min) | 4.5kgf/cm2 | 3.3~13.1 | 3.9~15.5 | 4.2~20.7 | 6.4~25.6 | |||||||

| 5.5kgf/cm2 | 2.9~11.5 | 3.4~14.5 | 4.8~19.0 | 5.9~23.6 | |||||||||

| 6.5kgf/cm2 | 2.4~10.5 | 3.2~13.3 | 4.5~17.5(+) | 5.6~21.5 | |||||||||

| 7.5kgf/cm2 | 2.3~10.0 | 3.0~13.1 | 4.2~16.6(+) | 5.3~20.8 | |||||||||

| 8.5kgf/cm2 | 2.2~8.6 | 2.8~12.3 | 3.8~15.6(+) | 4.9~20.0 | |||||||||

| 10.5kgf/cm2 | 1.9~7.5 | 2.3~10.1 | 3.4~13.6 | 4.1~16.3 | |||||||||

| 12.5kgf/cm2 | 1.6~6.4 | 2.3~9.0 | 2.9~11.5 | 3.9~15.3 | |||||||||

| Outlet Temperature(℃) | Ambient temperature+15℃ | ||||||||||||

| Outlet Pipe Diameter(inch) | 21/2 | 2 | 2 | 21/2 | 2 | DN65 | DN65 | 21/2 | DN100 | DN80| | DN65 | ||

| Transmission method | Direct Driven | ||||||||||||

| Lubricant Requirement(L) | 70 | 50 | 50 | 70 | 50 | 100 | 70 | 70 | 120 | 100 | 70 | ||

| Ventilation method | 25-100% automatical control, constant pressure output | ||||||||||||

| Oil content(ppm) | ≤3 | ||||||||||||

| Concuss(mm/s) | ≤7 | ||||||||||||

| Max Working Ambient Temperature(℃) | 52℃ | ||||||||||||

| Electric Motor | Power (kw) | 45 | 55 | 75 | 90 | ||||||||

| Starting method | Frequency conversion start | ||||||||||||

| Voltage | 380V/440V/660V | ||||||||||||

| Protection Level | IP55 | ||||||||||||

| Cooler | Cooling Type | air cooling or water cooling | |||||||||||

| Control method | Frequency conversion constant temperature control | ||||||||||||

| Fan Power(KW) | 2.2/1.5/1.35 | 2.2/2.2 | 2.2/2.2/2.2 | 4/4/2.2 | |||||||||

| Cooling Air Volume(m3/min) /Cooling water(t/h) | 180 | 250/9.5 | 280/12.8 | 340/15.5 | |||||||||

| Safety Indicating Device | safety valve/exhaust high tempenture protection/exhaust high pressure protection/over current protection/less phase protection/reversed phase protection | ||||||||||||

| Maintenance instructions | air filter/oil filter/oil-gas separator/lubricated oil | ||||||||||||

| Microcomputer control | digital temperature/pressure display controller/fully automatic operation/stop controller muti-machine interconnection controller(optional)/central monitoring extension function(optional) | ||||||||||||

| Noise(db) | 68 | 70 | 70 | 73 | |||||||||

| A Weight(kg) | 2100 | 2000 | 1700 | 2200 | 2000 | 2600 | 2400 | 2300 | 4000 | 3500 | 2600 | ||

| Air-Cooling | External Dimension | L(mm) | 2250 | 1850 | 1700 | 2250 | 1850 | 2450 | 2300(+) | 2250 | 2900 | 2750 | 2300 |

| W(mm) | 1370 | 1180 | 1130 | 1370 | 1180 | 1670 | 1670(+) | 1370 | 1940 | 1780 | 1670 | ||

| H(mm) | 1700 | 1430 | 1430 | 1700 | 1430 | 1740 | 1690(+) | 1700 | 1950 | 1950 | 1690 | ||

| W Weight(kg) | 2300 | 2000 | — | 2200 | 2000 | 3000 | 2400 | 2400 | 4000 | 3300 | 2600 | ||

| Water-Cooling | External Dimension | L(mm) | 2200 | 1800 | — | 2300 | 1800 | 2750 | 2300 | 2300 | 2900 | 2750 | 2300 |

| W(mm) | 1400 | 1320 | — | 1500 | 1320 | 1780 | 1500 | 1500 | 1940 | 1780 | 1500 | ||

| H(mm) | 1800 | 1370 | — | 1750 | 1370 | 1950 | 1750 | 1750 | 1950 | 1950 | 1750 | ||

| Machine Model | Max Working Pressure | SVC-110A/W II | SVC-120A/W II | SVC-132A/W II | SVC-150A/W II | SVC-160A/W II | SVC-185A/W II | ||||||||

| Compressor | Air Delivery (m3/min) | 4.5kgf/cm2 | 7.7~30.0 | 8.8~35.0 | 9.6~38.3 | 10.5~42.0 | 11.0-44.0 | 12.7~50.0 | |||||||

| 5.5kgf/cm2 | 7.2~28.2 | 7.9~30.0 | 8.8~35.0 | 9.6~38.3 | 10.5~42.0 | 11.5~46.0 | |||||||||

| 6.5kgf/cm2 | 6.7~26.6 | 7.2~28.2 | 7.8~33.0 | 8.8~35.0 | 9.6~38.3 | 11.0~44.0 | |||||||||

| 7.5kgf/cm2 | 6.1~24.5 | 6.5~26.0 | 7.2~30.0 | 8.1~33.0 | 8.8~35.0 | 10.7~42.0 | |||||||||

| 8.5kgf/cm2 | 5.8~23.5 | 6.1~24.8 | 6.9~28.0 | 7.4~30.0 | 8.1~33.0 | 10.3~40.0 | |||||||||

| 10.5kgf/cm2 | 5.1~20.1 | 5.6~22.9 | 6.1~24.1 | 6.5~28.0 | 7.7~30.0 | 8.8~35.5 | |||||||||

| 12.5kgf/cm2 | 4.4~17.3 | 4.7~19.2 | 5.4~21.3 | 6.1~24.3 | 6.5~26.3 | 7.5~32.4 | |||||||||

| Outlet Temperature(℃) | Ambient temperature+15℃ | ||||||||||||||

| Outlet Pipe Diameter(inch) | DN100 | DN80 | DN125 | DN100 | DN80 | DN125 | DN100 | DN125 | DN100 | DN125 | DN100 | DN125DN125 | |||

| Transmission method | Direct Driven | ||||||||||||||

| Lubricant Requirement(L) | 120 | 100 | 150 | 120 | 100 | 150 | 120 | 150 | 120 | 150 | 120 | 180 | 150 | ||

| Ventilation method | 25-100% automatical control, constant pressure output | ||||||||||||||

| Oil content(ppm) | ≤3 | ||||||||||||||

| Concuss(mm/s) | ≤7 | ||||||||||||||

| Max Working Ambient Temperature(℃) | 52℃ | ||||||||||||||

| Electric Motor | Power (kw) | 110 | 120 | 132 | 150 | 160 | 185 | ||||||||

| Starting method | Frequency conversion start | ||||||||||||||

| Voltage | 380V/440V/660V | ||||||||||||||

| Protection Level | IP55 | ||||||||||||||

| Cooler | Cooling Type | Air-cooling or water cooling | |||||||||||||

| Control method | Frequency conversion constant temperature control | ||||||||||||||

| Fan Power(KW) | 5.5/4 | 4/5.5/4 | 4/5.5 | 5.5/5.5 | 5.5/5.5 | 7.5/5.5 | |||||||||

| Cooling Air Volume(m3/min) /Cooling water(t/h) | 380/18.8 | 390/20.6 | 410/22.8 | 500/25.8 | 540/27.5 | 740/31.8 | |||||||||

| Safety Indicating Device | safety valve/exhaust high tempenture protection/exhaust high pressure protection/over current protection/less phase protection/reversed phase protection | ||||||||||||||

| Maintenance instructions | air filter/oil filter/oil-gas separator/lubricated oil | ||||||||||||||

| Microcomputer control | digital temperature/pressure display controller/fully automatic operation/stop controller muti-machine interconnection controller(optional)/central monitoring extension function(optional) | ||||||||||||||

| Noise(db) | 73 | 73 | 73 | 78 | 78 | 78 | |||||||||

| A Weight(kg) | 4100 | 3800 | 4600 | 4200 | 4000 | 4800 | 4300 | 5500 | 4400 | 5600 | 4500 | 6200 | 5800 | ||

| Air-Cooling | External Dimension | L(mm) | 2900 | 2750 | 2930 | 2900 | 2750 | 2930 | 2900 | 3250 | 2900 | 3250 | 2900 | 3500 | 3250 |

| W(mm) | 1940 | 1780 | 1900 | 1940 | 1780 | 1900 | 1940 | 1950 | 1940 | 1950 | 1940 | 2250 | 1950 | ||

| H(mm) | 1950 | 1950 | 2050 | 1950 | 1950 | 2060 | 1950 | 2150 | 1950 | 2150 | 1950 | 2300 | 2150 | ||

| W Weight(kg) | 3800 | 3400 | 4600 | 3900 | 3600 | 4800 | 4000 | 5000 | 4100 | 5200 | 4200 | 6000 | 5400 | ||

| Water-Cooling | External Dimension | L(mm) | 2900 | 2750 | 3250 | 2900 | 2750 | 3250 | 2900 | 3250 | 2900 | 3250 | 2900 | 3500 | 3250 |

| W(mm) | 1940 | 1780 | 1950 | 1940 | 1780 | 1950 | 1940 | 1950 | 1940 | 1950 | 1940 | 2100 | 1950 | ||

| H(mm) | 1950 | 1950 | 2150 | 1950 | 1950 | 2150 | 1950 | 2150 | 1950 | 2150 | 1950 | 2400 | 2150 | ||

| Machine Model | Max Working Pressure | SVC-200A/W II | SVC-220A/W II | SVC-250A/W II | SVC-280A/W II | SVC-300A/W II | SVC-330A/W II | |||||||

| Compressor | Air Delivery (m3/min) | 4.5kgf/cm2 | 13.7-55.0 | 15.3-61.0 | 16.3-65.0 | 19.2-76.9 | 20.6-825 | 21.3-85.5 | ||||||

| 5.5kgf/cm2 | 12.5-50.0 | 13.7-55.0 | 15.3-61.0 | 17.8-71.0 | 19.2-76.8 | 20.6-82.4 | ||||||||

| 6.5kgf/cm2 | 11.5-46.0 | 12.7-51.0 | 15.0-60.0 | 16.2-65.0 | 17.7-70.9 | 19.2-76.7 | ||||||||

| 7.5kgf/cm2 | 11.0-44.0 | 12.4-49.6 | 13.8-55.3 | 15.1-60.5 | 16.2-65.0 | 17.7-70.7 | ||||||||

| 8.5kgf/cm2 | 10.5-42.0 | 11.5-46.0 | 13.3-51.0 | 14.1-56.5 | 15.0-60.3 | 16.2-65.0 | ||||||||

| 10.5kgf/cm2 | 9.7-38.6 | 10.3-41.2 | 11.7-46.0 | 12.8-51.0 | 14.1-56.5 | 15.0-60.2 | ||||||||

| 12.5kgf/cm2 | 8.2-33.0 | 9.5-38.1 | 10.3-41.2 | 11.6-46.0 | 12.8-51.5 | 14.1-56.5 | ||||||||

| Outlet Temperature(℃) | Ambient temperature+15℃ | |||||||||||||

| Outlet Pipe Diameter(inch) | DN150 | DN125 | DN150 | DN125 | DN150 | DN125 | DN200 | DN150 | DN200 | DN150 | DN200 | DN150 | ||

| Transmission method | Direct Driven | |||||||||||||

| Lubricant Requirement(L) | 200 | 180 | 200 | 180 | 200 | 180 | 250 | 200 | 250 | 200 | 250 | 200 | ||

| Ventilation method | 25-100% automatical control, constant pressure output | |||||||||||||

| Oil content(ppm) | ≤3 | |||||||||||||

| Concuss(mm/s) | ≤7 | |||||||||||||

| Max Working Ambient Temperature(℃) | 52℃ | |||||||||||||

| Electric Motor | Power (kw) | 200 | 220 | 250 | 280 | 300 | 330 | |||||||

| Starting method | Frequency conversion start | |||||||||||||

| Voltage | 380V/440V/660V | |||||||||||||

| Protection Level | IP55 | |||||||||||||

| Cooler | Cooling Type | Air-cooling or water cooling | ||||||||||||

| Control method | Frequency conversion constant temperature control | |||||||||||||

| Fan Power(KW) | 11/7.5 | 11/7.5 | 11/7.5 | 15/11 | 15/15 | 15/15 | ||||||||

| Cooling Air Volume(m3/min) /Cooling water(t/h) | 780/34.3 | 800/37.8 | 840/43.0 | 860/48.1 | 880/50 | 880/50 | ||||||||

| Safety Indicating Device | safety valve/exhaust high tempenture protection/exhaust high pressure protection/over current protection/less phase protection/reversed phase protection | |||||||||||||

| Maintenance instructions | air filter/oil filter/oil-gas separator/lubricated oil | |||||||||||||

| Microcomputer control | digital temperature/pressure display controller/fully automatic operation/stop controller muti-machine interconnection controller(optional)/central monitoring extension function(optional) | |||||||||||||

| Noise(db) | 80 | 80 | 82 | 82 | 85 | 85 | ||||||||

| A Weight(kg) | 7600 | 6200 | 7800 | 6400 | 8000 | 6600 | 8800 | 8100 | 9000 | 8300 | 9300 | 8600 | ||

| Air-Cooling | External Dimension | L(mm) | 3800 | 3500 | 3800 | 3500 | 3800 | 3500 | 4300 | 3800 | 4300 | 3800 | 4300 | 3800 |

| W(mm) | 2300 | 2250 | 2300 | 2250 | 2300 | 2250 | 2400 | 2300 | 2400 | 2300 | 2400 | 2300 | ||

| H(mm) | 2400 | 2300 | 2400 | 2300 | 2400 | 2300 | 2600 | 2400 | 2600 | 2400 | 2600 | 2400 | ||

| W Weight(kg) | 7300 | 6000 | 7500 | 6200 | 7700 | 6400 | 8500 | 7800 | 8700 | 8000 | 9000 | 8300 | ||

| Water-Cooling | External Dimension | L(mm) | 3800 | 3500 | 3800 | 3500 | 3800 | 3500 | 4000 | 3800 | 4000 | 3800 | 4000 | 3800 |

| W(mm) | 2300 | 2100 | 2300 | 2100 | 2300 | 2100 | 2400 | 2300 | 2400 | 2300 | 2400 | 2300 | ||

| H(mm) | 2400 | 2400 | 2400 | 2400 | 2400 | 2400 | 2650 | 2400 | 2650 | 2400 | 2650 | 2400 | ||

English

English

Chine

Chine

Russia

Russia

France

France

Spain

Spain

Arab

Arab