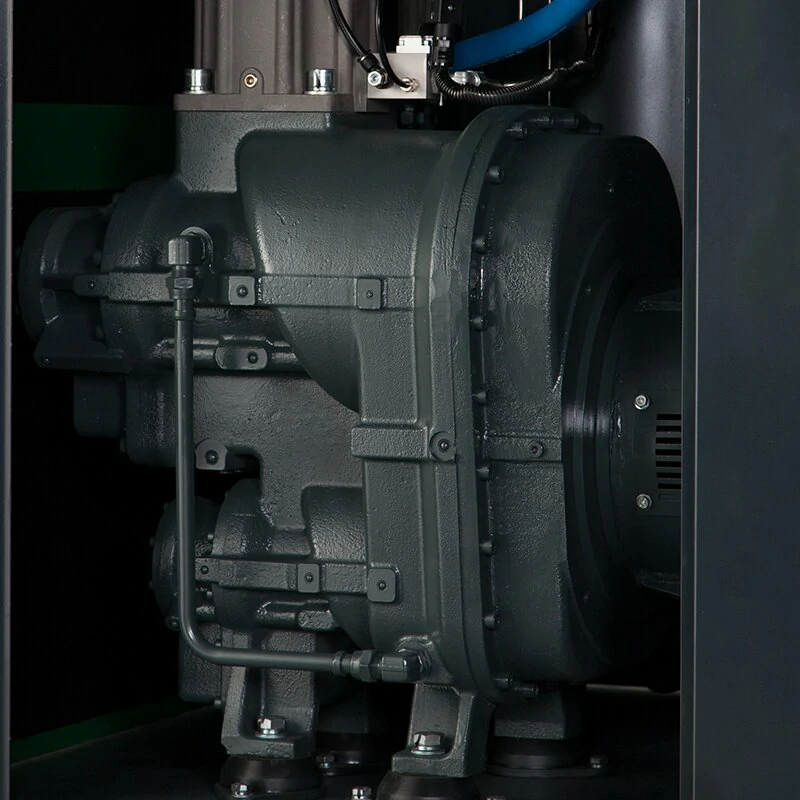

High efficiency frequency one-stage compression screw air compressor

Working pressure: 7-12.5 bar

Capacity: 0.47-15.4 m3/min

Power: 5.5-90 kw

Product advantages

01Control system

1. LCD high-definition touch display, intuitive interface, humanized menu structure design

2. Can display multiple lines of operating parameters and historical records

3. Adopt well-known electronic control components, easy to operate, query and maintain

02High-efficiency intake valve

1. Large diameter, low pressure drop

2. Improve the stability of the system

3. Ensure effective regulation and control of flow during startup, operation and shutdown

03Cooling system

1. Centrifugal cooling fan, quiet and efficient

2. Oil cooling fan, variable frequency start

3. Low power consumption, low noise

04High-efficiency motor

1. Large starting torque

2. Insulation grade F, protection grade IP54

3. SKF Bearing, low noise, long service life

4. Equipped with refueling device, refueling can be done without stopping the machine

05 alloy steel pipeline connection

1. Excellent mechanical properties, superior wear resistance;

2. Excellent corrosion resistance;

3. Can work safely for a long time at a temperature of -270℃-400℃, no harmful substances will be precipitated at high or low temperatures, and the material properties are quite stable;

4. Wide range of use, long service life and low comprehensive cost. Corrosion test data show that the service life of alloy steel pipes can reach 100 years, and almost no maintenance is required during the life cycle, avoiding the cost and trouble of pipeline replacement.

Technical parameters

| Machine Model | Max Working Pressure | S-06A | S-08A | S-11A | S-15A | S-18A | S-22A | |

| Compressor | Air Delivery (m3/min) |

7.0kgf/cm2 | 0.85 | 1.17 | 1.84 | 2.40 | 2.98 | 3.42 |

| 8.0kgf/cm2 | 0.78 | 1.08 | 1.74 | 2.32 | 2.90 | 3.37 | ||

| 10.0kgf/cm2 | 0.61 | 0.87 | 1.25 | 1.69 | 2.54 | 2.90 | ||

| 12.5kgf/cm2 | 0.47 | 0.70 | 1.02 | 1.62 | 1.65 | 2.35 | ||

| Outlet Temperature(℃) | Ambient temperature+15℃ | |||||||

| Outlet Pipe Diameter(inch) | G3/4 | G3/4 | G3/4 | G3/4 | G1 | G1 | ||

| Transmission method | Skin joint | Direct Driven | ||||||

| Lubricant Requirement(L) | 10 | 10 | 18 | 18 | 18 | 18 | ||

| Ventilation method | ON/OFF | |||||||

| Oil content(ppm) | ≤3 | |||||||

| Concuss(mm/s) | ≤7 | |||||||

| Max Working Ambient Temperature(℃) | 52℃ | |||||||

| Electric Motor | Power (kw) | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | |

| Starting method | Direct start | Y-△ start | ||||||

| Voltage | 380V | |||||||

| Protection Level | IP55 | |||||||

| Cooler | Cooling Type | Air-cooling | ||||||

| Control method | Intelligent controls | |||||||

| Fan Power(KW) | 0.12 | 0.12 | 0.37 | 0.37 | 0.75 | 0.75 | ||

| Cooling Air Volume(m3/min) /Cooling water(t/h) |

19 | 26 | 37 | 52 | 63 | 75 | ||

| Safety Indicating Device | safety valve/exhaust high tempenture protection/exhaust high pressure protection/over current protection/less phase protection/reversed phase protection | |||||||

| Maintenance instructions | air filter/oil filter/oil-gas separator/lubricated oil | |||||||

| Microcomputer control | digital temperature/pressure display controller/fully automatic operation/stop controller muti-machine interconnection controller(optional)/central monitoring extension function(optional) | |||||||

| Noise(db) | 60 | 60 | 60 | 65 | 65 | 65 | ||

| Weight(kg) | 320 | 350 | 450 | 500 | 550 | 600 | ||

| External Dimension | Length(mm) | 760 | 760 | 1200 | 1200 | 1350 | 1350 | |

| Width(mm) | 760 | 760 | 750 | 750 | 850 | 850 | ||

| Height(mm) | 1065 | 1065 | 1050 | 1050 | 1170 | 1170 | ||

| Machine Model | Max Working Pressure | S-30A | S-37A | S-45A | S-55A/W | S-75A/W | S-90A/W | ||

| Compressor | Air Delivery (m3/min) |

7.0kgf/cm2 | 5.20 | 6.22 | 7.34 | 9.54 | 12.30 | 15.40 | |

| 8.0kgf/cm2 | 5.10 | 6.17 | 7.24 | 9.44 | 12.20 | 15.30 | |||

| 10.0kgf/cm2 | 3.32 | 5.00 | 4.80 | 7.14 | 6.01 | 12.10 | |||

| 12.5kgf/cm2 | 3.16 | 6.83 | 5.81 | 9.32 | 9.10 | 11.68 | |||

| Outlet Temperature(℃) | Ambient temperature+15℃ | ||||||||

| Outlet Pipe Diameter(inch) | G1 1/2 | G1 1/2 | G1 1/2 | G2 | G2 | DN65 | G2 | ||

| Transmission method | Direct Driven | ||||||||

| Lubricant Requirement(L) | 20 | 20 | 30 | 40 | 60 | 70 | |||

| Ventilation method | ON/OFF | ||||||||

| Oil content(ppm) | ≤3 | ||||||||

| Concuss(mm/s) | ≤7 | ||||||||

| Max Working Ambient Temperature(℃) | 52℃ | ||||||||

| Electric Motor | Power (kw) | 30 | 37 | 45 | 55 | 75 | 90 | ||

| Starting method | Y-△ start | ||||||||

| Voltage | 380V | ||||||||

| Protection Level | IP55 | ||||||||

| Cooler | Cooling Type | Air-cooling | Air-cooling or water cooling | ||||||

| Control method | Intelligent controls | ||||||||

| Fan Power(KW) | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | |||

| Cooling Air Volume(m3/min) /Cooling water(t/h) |

103 | 127 | 155 | 189/9.5 | 258/12.9 | 310/15.5 | |||

| Safety Indicating Device | safety valve/exhaust high tempenture protection/exhaust high pressure protection/over current protection/less phase protection/reversed phase protection | ||||||||

| Maintenance instructions | air filter/oil filter/oil-gas separator/lubricated oil | ||||||||

| Microcomputer control | digital temperature/pressure display controller/fully automatic operation/stop controller muti-machine interconnection controller(optional)/central monitoring extension function(optional) | ||||||||

| Noise(db) | 68 | 68 | 68 | 72 | 72 | 75 | |||

| Weight(kg) | 1000 | 1000 | 1200 | 1500 | 1800 | 2000 | 1900 | ||

| External Dimension | Length(mm) | 1580 | 1580 | 1530 | 1700 | 1850 | 2100 | 2100 | |

| Width(mm) | 920 | 920 | 1000 | 1180 | 1250 | 1370 | 1370 | ||

| Height(mm) | 1220 | 1220 | 1480 | 1650 | 1650 | 1700 | 1700 | ||

1、Overall dimensions, export pipe diameter, weight, and the data consistent color.

2、Air-cooling, water cooling.

3、Technical parameter may change without notice, please kindly understand that.

4、10kg and 12.5kg please refer to the actual drawings.

English

English

Chine

Chine

Russia

Russia

France

France

Spain

Spain

Arab

Arab