How to Choose a Durable Industrial Air Compressor for Demanding Applications

Selecting the right industrial air compressor is a critical decision for factory procurement managers and engineers.

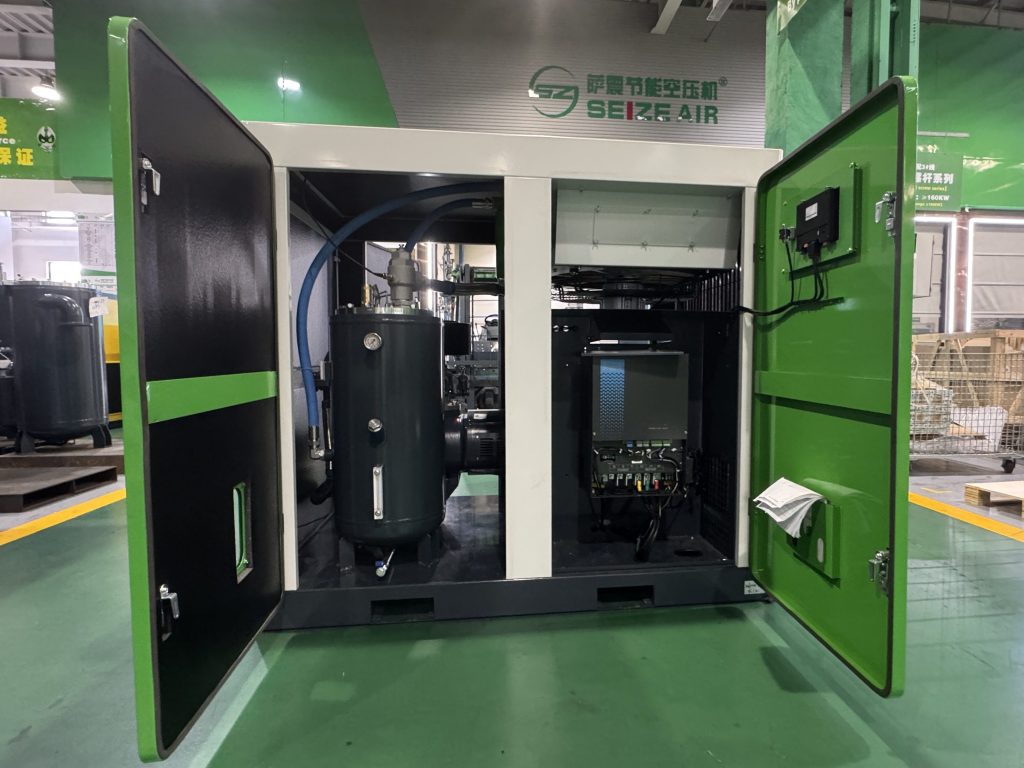

The challenge often lies in finding a machine that delivers consistent performance under tough conditions like high temperatures and variable demand, without incurring excessive energy or maintenance costs. While many options exist, modern industrial air compressor systems, particularly micro-oil screw types, are engineered to meet these rigorous demands effectively.

Why Reliability is the Cornerstone of Compressor Selection?

Firstly, reliability is the most crucial factor for any industrial application.

Unexpected downtime halts production lines, leading to significant financial losses. Consequently, a compressor’s design and construction directly impact its operational lifespan and dependability. Robust components, such as high-grade cast iron rotors and housings, are essential for withstanding continuous operation.

Furthermore, advanced cooling systems are vital for maintaining optimal temperatures, even in hot factory environments. By prioritizing these engineering principles, manufacturers ensure that the compressor remains a dependable asset, not a recurring problem.

Key Features That Define a Superior Industrial Compressor

Modern industrial needs require compressors with specific performance advantages. When evaluating options, several key features stand out for their ability to enhance efficiency and adaptability.

- High-Temperature Resistance: A compressor’s ability to perform reliably in elevated ambient temperatures is a mark of superior engineering. Engineered with efficient cooling systems, these compressors achieve reliable high-temperature operation, preventing the overheating that causes unplanned shutdowns.

- Low-Pressure Operation Capabilities: Specifically designed for low-pressure applications like pneumatic conveying, these compressors achieve the same result with substantially lower energy consumption and direct cost savings.

- Variable Frequency Drive (VFD) Technology: By adjusting motor speed to match air demand, VFD technology eliminates energy waste from frequent cycling, reducing consumption by up to 35% and minimizing mechanical stress to extend component life.

- Quiet Operation Design: To address growing noise pollution concerns, quiet compressors utilize specialized enclosures and low-vibration components to create a safer and more productive workspace, particularly when operating near personnel.

Critical Applications Across Modern Industry

The versatility of modern screw compressors makes them suitable for a vast range of sectors.

- In manufacturing, they power assembly line tools, automation equipment, and packaging machinery.

- The construction and mining industries rely on them for operating heavy pneumatic tools and controls in harsh conditions.

- Additionally, they are indispensable in sectors like plastics manufacturing for injection molding and blow molding processes.

Their robust design ensures a continuous supply of clean, dry air, which is the lifeblood of modern industrial operations.

A Strategic Guide to Sizing and Selection:

Choosing the correct compressor involves a systematic evaluation of your plant’s specific needs.

- Initially, you must accurately determine your required air flow (CFM or m³/min) and working pressure (PSI or bar). Undersizing leads to pressure drops and equipment failure, while oversizing results in wasted energy.

- Subsequently, analyze your air demand profile. If demand fluctuates significantly, a VFD compressor is likely the most economical choice.

- Furthermore, consider the air quality requirements; for most industrial applications, a micro-oil screw compressor with appropriate filtration delivers exceptionally clean air efficiently.

- Finally, always evaluate the total cost of ownership, which includes the initial purchase price, energy costs over the unit’s life, and projected maintenance expenses.

By adhering to this systematic selection process, you can significantly reduce operational risks and optimise energy efficiency. SEIZE AIR, as a Chinese enterprise specialising in screw air compressor manufacturing, develops its products with a strong focus on these core requirements of industrial users.

Conclusion

A strategic approach to selecting an industrial air compressor focuses on core features that guarantee reliability, energy efficiency, and adaptability. Key considerations like high-temperature resilience, efficient low-pressure operation, VFD technology, and quiet performance are no longer luxuries but necessities for a competitive operation.

For those seeking a robust solution that embodies these principles, it is worth exploring specialized manufacturers. Seize Air, is a Chinese manufacturer known for its reliable and energy-efficient screw air compressors, which are engineered to deliver durable performance in a wide range of industrial applications.

English

English

Chine

Chine

Russia

Russia

France

France

Spain

Spain

Arab

Arab