Oil-Free Two-Stage Air Compressors: 4 Stages to Avoid Mistakes

When factories purchase oil-free two-stage air compressors, they often make wrong selections due to poor understanding of processes. This results in either unqualified air supply or high energy consumption. This article breaks down 4 core processes of oil-free two-stage air compressors. It helps you grasp the full logic of “air treatment-storage-cooling-energy saving” to choose and use the right equipment.

Air Compression & Preliminary Purification (Core component)

The oil-free two-stage screw airend (take SEIZEAIR’s high-config dry oil-free two-stage screw air compressor as an example) is the core compression device. It adopts two-stage compression + oil-free design. This design not only improves compression efficiency but also delivers oil-free clean compressed air. It meets the needs of industries like medical and food that require high air quality.

After compression, the air enters the pre-treatment device. It goes through filtration and impurity removal steps. These steps initially remove dust, particles and other impurities from the air. They lay a solid foundation for the subsequent drying stage.

Air Drying & Deep Purification

The preliminarily purified air enters the drying system (such as non-powered drying units or adsorption dryers). It uses physical or chemical methods to remove moisture from the air. This ensures the dew point of compressed air meets standards (usually as low as -40℃ or below). It avoids equipment failures or product quality issues caused by moisture.

The dried air then passes through precision filters. These filters further remove tiny oil mist and particles. They raise the cleanliness of compressed air to higher standards (e.g., Class 0 oil-free standard).

Air Storage & Stable Delivery

Clean compressed air is sent to the air storage tank. The tank serves two key purposes: First, it stabilizes air pressure. This prevents frequent loading and unloading of the air compressor and reduces energy consumption.

Second, it stores air for backup. When the factory’s peak air demand fluctuates, the tank can supply air in time to ensure stable air use.

Compressed air from the storage tank is delivered to various air-use ends via pipeline systems. These include production equipment and pneumatic tools. It meets air needs in different scenarios.

Cooling Water Circulation & Waste Heat Recovery (Dual-Effect Energy Saving)

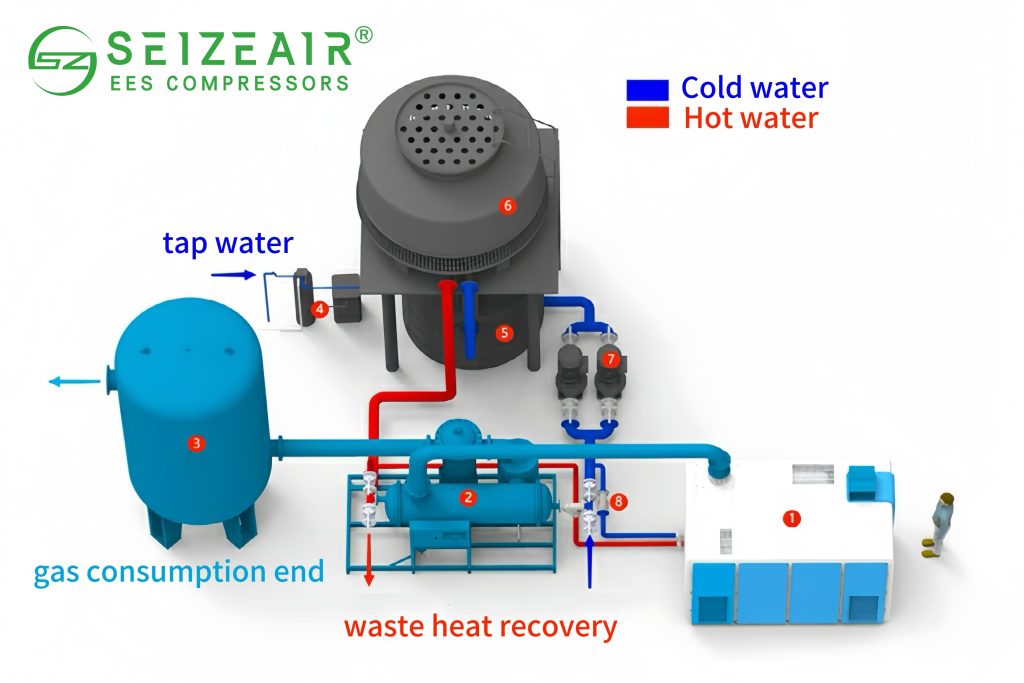

Take SEIZEAIR’s supporting cooling and waste heat recovery system as an example.

The whole process connects closely:

- Soft Water Pre-Treatment: Tap water first enters the water softener unit. It removes calcium and magnesium ions from the water. This prevents pipe scaling and extends equipment life.⭐

- Cooling Water Circulation: Softened water enters the water storage tank. A water pump sends it to the cooling tower. Cooled water (via blue pipelines) is delivered to the cooling system of the oil-free two-stage air compressor. It cools parts like the airend and motor. This ensures the equipment runs at a suitable temperature.⭐

- Waste Heat Recovery & Utilization: Hot water (via red pipelines) from the air compressor’s cooling process enters the waste heat recovery device. It recovers heat that would otherwise go to waste. This heat can be used for factory heating, hot water supply, etc. It enables secondary energy use and cuts the factory’s overall energy costs.⭐

- Impurity Filtration: A Y-type filter is installed in the water system. It filters impurities from the water. This keeps the cooling water circulation system clean and smooth.⭐

In summary, the process of oil-free two-stage air compressors focuses on “clean air output” and “efficient energy-saving operation”. Every stage—from compression and purification to storage and cooling—affects the equipment’s performance and air supply effect. If your factory plans to use oil-free two-stage air compressors, you can send a message to get Oil-Free Air Compressor Selection & Process Matching Table. It helps you plan equipment configuration accurately.

SEIZEAIR:High efficiency, low energy consumption, reliable performance. Perfect for your industrial needs. Choose SEIZEAIR, save costs & boost productivity!

Address:No.188 Jinliu Road,Jinshan industrial zone,Jinshan district,Shanghai, China

Whatsapp:+86-15317057736 | +86-15021218862

E-Mail:sales@seize-air.com | sales-ru@seize-air.com

Contact us right now?

English

English

Chine

Chine

Russia

Russia

France

France

Spain

Spain

Arab

Arab