Why Permanent Magnet Two-Stage Air Compressors Are the Future of Efficient Manufacturing

According to a recent report from the International Energy Agency (IEA), industrial energy consumption accounts for over 30% of global energy usage, with compressed air systems alone contributing to 10-20% of a factory’s energy costs.

Energy prices are rising, and sustainability is gaining importance. As a result, procurement managers and engineers face growing pressure to find energy-efficient solutions.One promising option is advanced compressor technology.

The permanent magnet two-stage air compressor is a standout solution that reduces energy consumption and enhances operational reliability. This makes it an attractive option for manufacturers looking to reduce costs and increase productivity.

The Advantages of Permanent Magnet Two-Stage Air Compressors

The permanent magnet two-stage air compressor is transforming the manufacturing sector. By combining the advantages of a two-stage compression process with a permanent magnet motor. The two-stage system enables higher air pressure efficiency, and the permanent magnet motor significantly reduces energy consumption.

This innovative design makes the compressor much more efficient than traditional models, particularly for industries requiring continuous, high-volume compressed air.

Energy Efficiency and Cost Savings

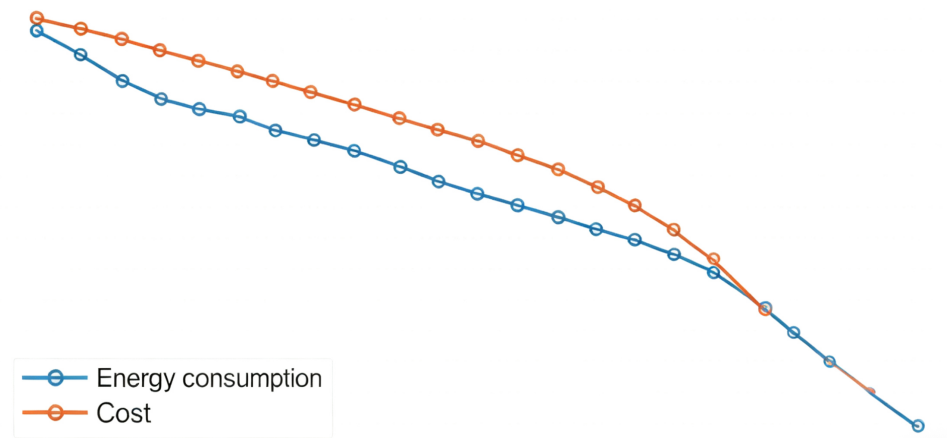

One of the most compelling reasons to adopt a permanent magnet two-stage air compressor is its energy efficiency.

Equipped with a permanent magnet motor, these compressors consume less electricity than conventional induction motor-driven units.

Studies indicate that such compressors can save up to 30% in energy costs over their entire lifespan.

This reduced energy consumption directly lowers factories’ operational costs, helping procurement managers achieve a faster return on investment (ROI).

Longer Service Life and Reliability

A key advantage of the permanent magnet two-stage air compressor is its reliability and durability. Thanks to advanced motor technology and a two-stage compression system, these compressors experience less wear and tear than traditional models. Consequently, they have a significantly longer service life, making them a more cost-effective solution in the long term. The permanent magnet motor also reduces vibration, resulting in quieter operation and fewer breakdowns — ideal for continuous manufacturing environments.

Reduced Maintenance and Operational Costs

Thanks to the minimal maintenance required for permanent magnet two-stage compressors, companies can benefit from reduced downtime and lower maintenance costs. With fewer moving parts and more robust motor components, these compressors require less frequent servicing. This cuts maintenance costs and minimises the risk of unexpected failures, making these compressors an excellent option for factories that rely on consistent performance.

Adaptability for Various Industrial Applications

The permanent magnet two-stage air compressor is highly adaptable, making it suitable for a wide range of industries. Whether in automotive manufacturing, food processing, or pharmaceutical production, these compressors can be tailored to meet specific pressure and flow requirements. This versatility is crucial for procurement managers looking for flexible and reliable air compression solutions that meet the diverse needs of modern factories.

Conclusion

The two-stage permanent magnet air compressor offers significant advantages in terms of energy efficiency, cost savings and reliability. Its advanced design enables manufacturers to reduce energy use while boosting productivity. For procurement managers and engineers searching for solutions that deliver short- and long-term value, this technology is an exceptional choice.

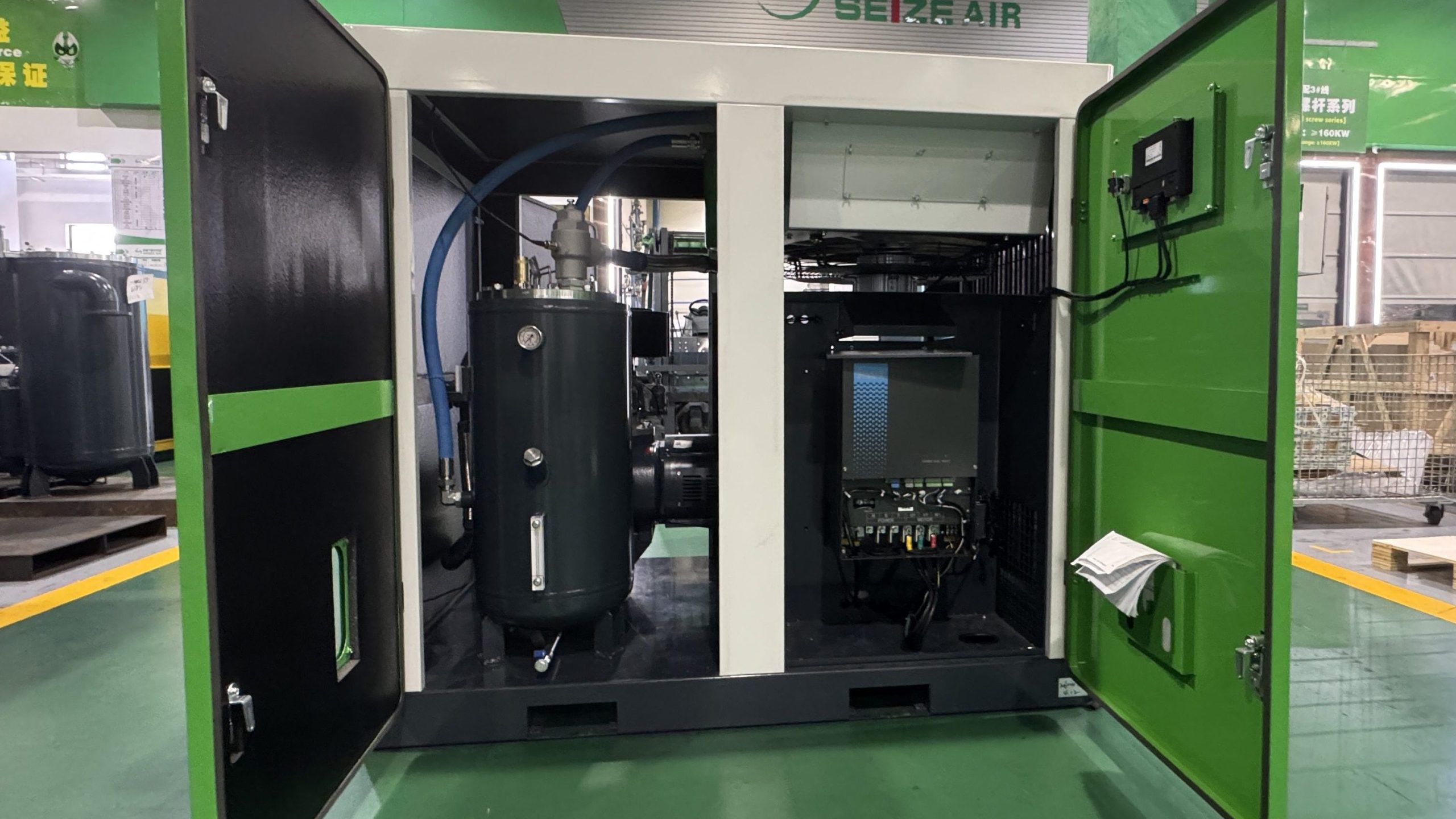

As a leading Chinese manufacturer of air compressors, Seize Air specialises in providing reliable, energy-efficient, oil-free screw air compressors. With a focus on sustainability and performance, Seize Air’s products are designed to optimise operations and reduce costs, making them a smart investment for modern factories.

English

English

Chine

Chine

Russia

Russia

France

France

Spain

Spain

Arab

Arab